CEEPR Working Paper 2021-012, July 2021

Andrew T. Bouma, Quantum J. Wei, John E. Parsons, Jacopo Buongiorno and John H. Lienhard V

Photo credit: Diablo Canyon Nuclear Power Plant, Units 1 and 2, by US Nuclear Regulatory Commission

California has a pressing need for additional sustainable fresh water supplies. This report explores the feasibility and economic benefits of co-locating a large seawater desalination plant at the Diablo Canyon Nuclear Power Plant (DCNPP) to supply potable water to the state. A key challenge for any desalination plant and for continued operation of DCNPP is compliance with California’s regulations protecting marine organisms from large intake structures. We show how a new brushed-screen intake structure, serving both the nuclear power plant and the desalination plant, achieves compliance. This arrangement integrates the desalination plant with the nuclear power plant by sharing infrastructure and receiving feedwater and power from the nuclear power plant, forming a water-power coproduction system. The cost of desalinated water from coproduction is much cheaper than the cost from an alternative stand-alone plant.

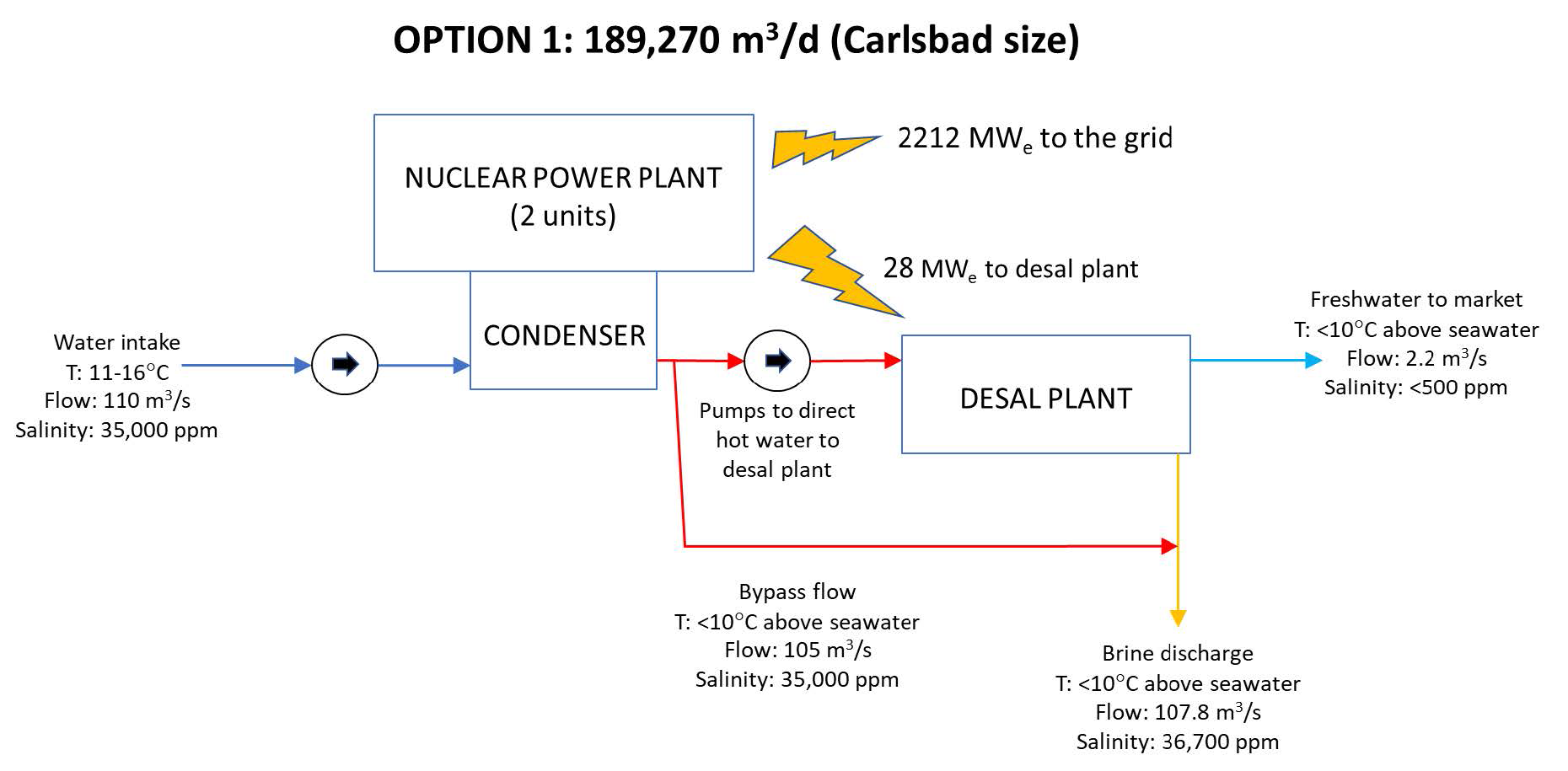

We evaluated four options for configuring a seawater reverse osmosis desalination plant at the DCNPP. The smallest option (see Figure 1 in the next section) has a capacity of about 190,000 m3/d, which is also the nameplate capacity of the Carlsbad Desalination Plant in San Diego County, and approximately the same size as the proposed plant at Huntington Beach. There are a number of interesting benefits of building at this scale, including lower salinity brines after the desalination brine is mixed with the power plant cooling water, which would obviate the need for high-energy diffuser outfalls and allow for the existing outfall infrastructure to remain in place. In this configuration, the electrical requirement of the desalination plant is very small compared to the size of the nuclear power plant.

A key challenge for any desalination plant and for continued operation of DCNPP is compliance with California’s regulations protecting marine organisms from large intake structures. The California Ocean Plan regulates intakes for desalination plants and places strict limits on the impingement and entrainment of marine life. A separate regulation for power plants requires existing power plants using once-through cooling to reduce their intake flow rate by 93%. If not feasible, power plants are able to instead put into place measures that reduce the impingement and entrainment of marine life for the facility by a comparable level. These regulations are the primary technical reason for the impending shutdown of DCNPP.

The compliance option we incorporate into our analysis is the construction of submerged screen intakes with a mesh size of 1 mm or less, and a flow velocity at the screen of no more than 0.5 feet per second (15 cm/s). Although these conditions can lead to rapid fouling of the intake screens, screens can be cleaned by a number of methods, such as with an air burst, mechanical cleaning, or by divers. For the purpose of this analysis, though, Intake Screens, Inc. (ISI) of Sacramento has provided us initial estimates regarding mechanical brush-cleaned wedgewire screens, which will likely be one of the most competitive options. Similar intake systems have been specified for the Huntington Beach desalination plant and are currently being tested at Carlsbad as a potential replacement for the existing intake. Key to ISI’s design is a submersible electric-drive assembly that rotates wedgewire screen cylinders between nylon brushes. The exterior of the wedgewire is cleaned by a fixed position external brush and the interior of the screen is cleaned by an internal brush that rotates. This brush-cleaning system has proven effective at maintaining a clean screen surface in a number of applications with challenging fouling environments.

To place the screens in an appropriate offshore, deep water location that minimizes potential impacts to aquatic resources, the existing shoreline basin would be closed off from the Pacific Ocean by extending the existing breakwater structure, and a drop shaft constructed to a bored tunnel approximately 335 meters long terminating at the manifold array. This arrangement allows for the power plant to continue to operate continuously throughout the construction of the new intake, as the existing power plant intake pumps and structure are unchanged (see Figure 2).

There are significant economic advantages for a DCNPP-desalination coproduction plant as compared against an alternative stand-alone desalination plant. The savings from sharing of the new intake and existing outfall structures are significant. In addition, the cost of power is substantially reduced. The levelized cost of water for the smallest option is estimated at $0.98 per m3 at the plant outlet, as compared against $1.84 per m3 from a comparable stand-alone desalination plant.

The scope of our analysis has been limited to techno-economic feasibility, and we find that co-locating a desalination plant at Diablo Canyon is technically feasible and economically beneficial. Of course, myriad additional factors should be considered before Californians make a judgment on whether such a plant is the preferred solution for water needs of the California Central Coast or for wider parts of the state.

Figure 1. Option 1: Large scale desalination plant similar to existing plants

Figure 2. Aerial view of DCNPP with extended breakwater to isolate lagoon, emergency inlet structure, tunnel extending offshore, and wedgewire screen array for Option 1 configuration outlined in Figure 1.

References

Bouma, Andrew T., Q. J. Wei, J.E. Parsons, J. Buongiorno, and J. H. Lienhard V (2021), “Water for a Warming Climate: A Feasibility Study of Repurposing Diablo Canyon Nuclear Power Plant for Desalination.” MIT CEEPR Working Paper 2021-012, July 2021.